Loading... Please wait...

Loading... Please wait...- 1-800-874-1935

- Home

- My Account

- View Cart

Categories

- Home

- Components

- Hanger Bearings

- Nylon/Nylatron Hanger Bearing (Style 220/226)

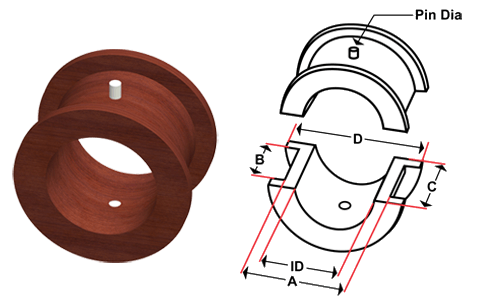

Nylon/Nylatron Hanger Bearing (Style 220/226)

Product Description

Normally, with a product or component which brings about an accelerated performance, longer life, or more trouble free operation, the cost is usually justifiably higher than conventional components. . . yet, in the case of nylon bearings, the initial cost is LESS, or at least comparable to ordinary bearings.

Coupled with this initial economy, numerous other savings are realized through lower maintenance, less wear on coupling shafts and the reduction of profit robbing down time.

Their longer life, corrosion and abrasion resistance, makes them cost effective. Most chemicals fail to impair their smooth operation. There is less heat generated during use, hence, they maintain established fits and running clearances over a greater temperature range.

Lubrication is normally desirable since it will improve the PV (Pressure and Velocity) rating as much as five times. However, the built in lubricant (molybdenum disulfide) is adequate in the event of lubricant failures. Depending upon loads, speeds and materials conveyed, bearings can, and have been, operated successfully with no lubrication.

While the use of nylon bearings is primarily intended for most conveyor hanger applications involving moderate loads and speeds in temperature ranges of -40°F-to + 220°F I -40°C to + 104°C the unexcelled properties of this material will suggest other applications to the user.

Multiple styles are available for purchase in various sizes. Please call us at 1-800-874-1935 for more information and a quote on Nylatron Hanger Bearings.

|

Part No. |

ID |

A |

B |

C |

D |

|

NB-108 |

1-1/2" |

2-1/8" |

1-9/16" |

1-15/16" |

2-1/2" |

|

NB-200 |

2" |

2-3/4" |

1-9/16" |

1-15/16" |

3-1/8" |

|

NB-207 |

2-7/16" |

3-1/4" |

2-3/8" |

2-15/16" |

3-3/4" |

|

NB-300 |

3 |

4 |

2-3/8" |

2-15/16" |

4-1/2" |

|

NB-307 |

3-7/16" |

4-3/4" |

3-1/8" |

3-15/16" |

5-1/2" |